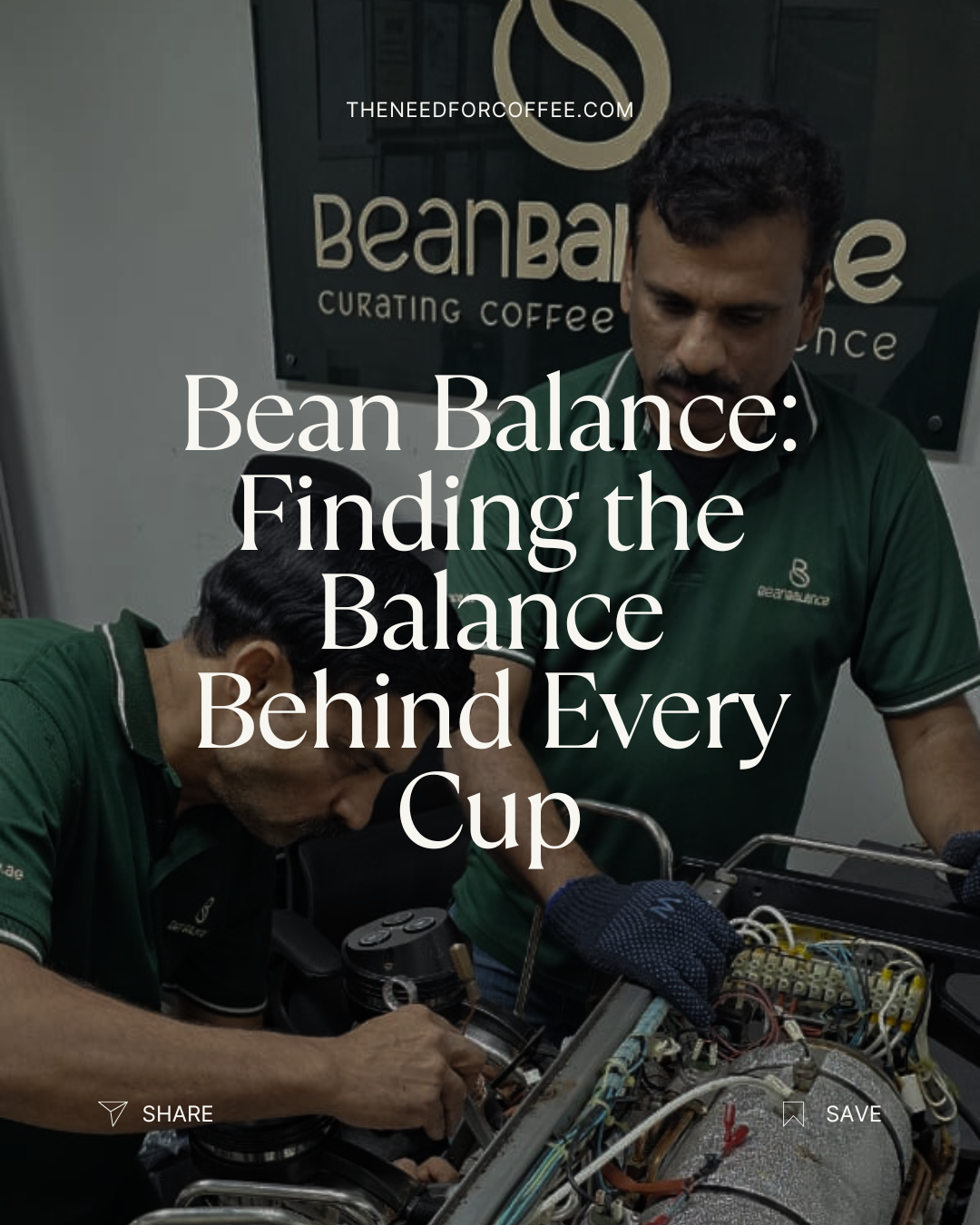

Bean Balance: Finding the Balance Behind Every Cup

In many cafés, the coffee machine is treated like a background character. As long as it turns on and pushes out espresso, it’s considered “working.” But anyone who has tasted the same coffee prepared on two different machines knows that performance is only half the story. The other half lives in calibration, water quality, temperature stability, and countless other parameters set behind the counter.

This is the space where Bean Balance was born.

The company didn’t start with a single lightbulb moment, but with years of experience inside the coffee industry. Ramesh and Rashid, the founders had worked closely with machines, baristas, and café owners long enough to notice a pattern. “Coffee technical work is not just a normal technical job,” they explain. “It needs proper technical skill, beverage knowledge, and a good understanding of coffee and coffee-based drinks.”

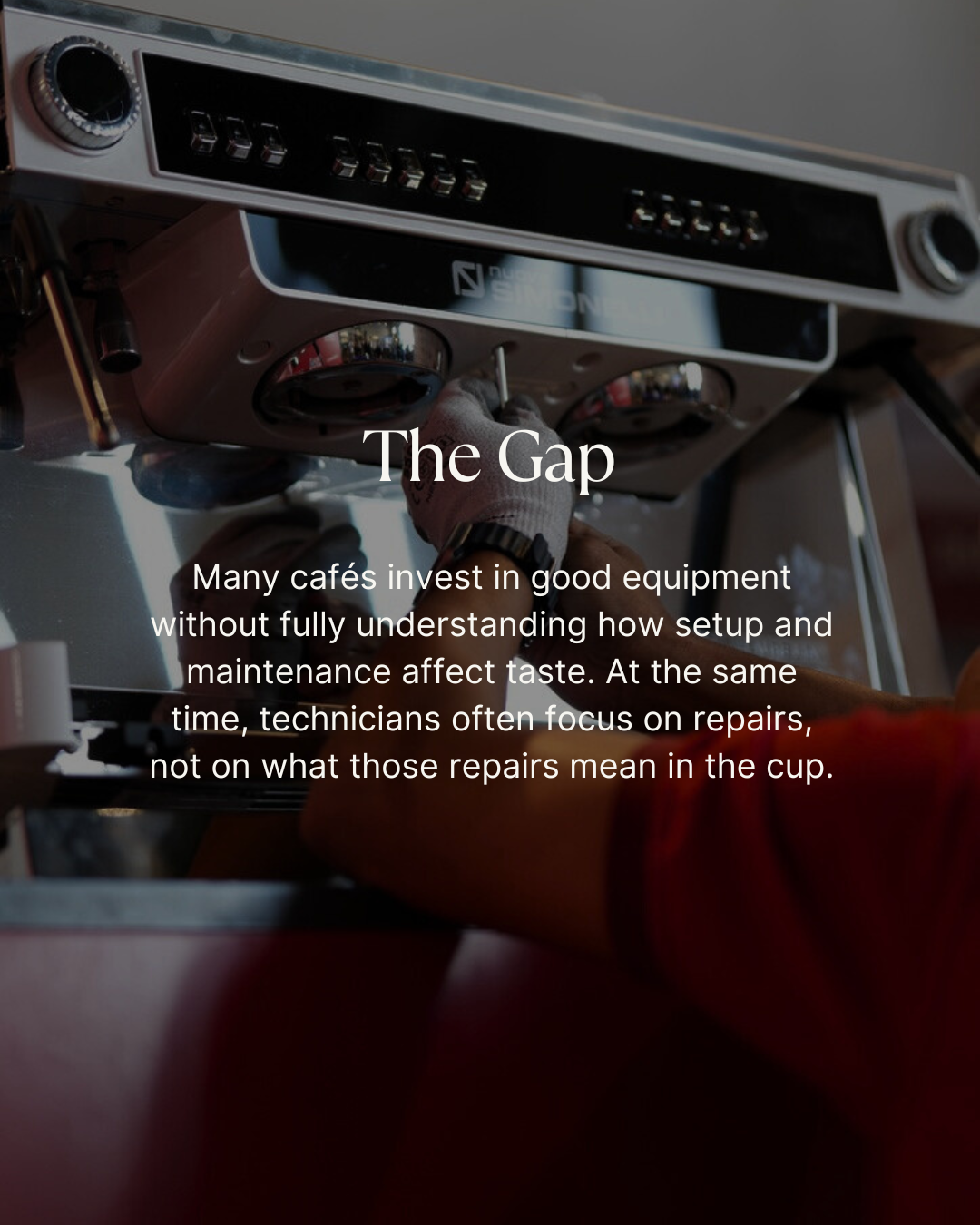

What stood out most was the disconnect. Many cafés were investing in good equipment, but without fully understanding how machine setup and maintenance directly affect taste. At the same time, technicians were often focused only on repairs, not on what those repairs meant for the cup. That gap became the motivation. Bean Balance set out to work on both sides of the equation: the machine and the coffee it produces.

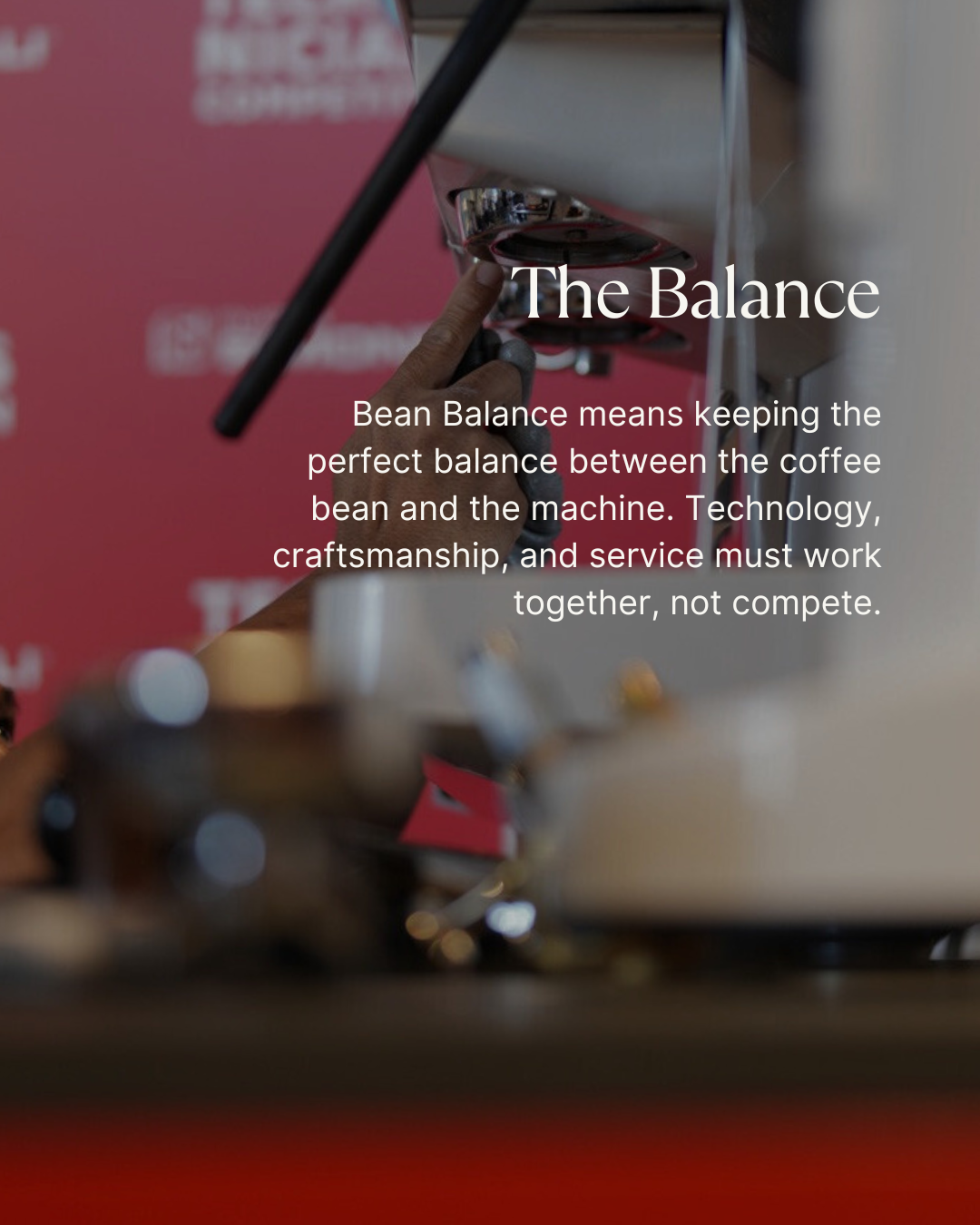

The name reflects that idea simply. “Bean Balance means keeping the perfect balance between the coffee bean and the machine.” It’s a practical philosophy, not a slogan. Technology, craftsmanship, and service have to work together, not compete. As they put it, balance is “using good technology, proper coffee knowledge, and helpful service together to give the best coffee experience.”

This approach quickly set them apart in the region. Bean Balance doesn’t tie itself to a single brand or setup. Instead, the team services a wide range of machines and environments, from small neighborhood cafés to large hotels and high-traffic locations. “We understand both the machine and the coffee,” they say. “We combine technical skills with real coffee knowledge, and we are very reachable. We support customers anywhere without restrictions.”

That flexibility matters even more in the Middle East, where climate plays a major role in coffee quality. High ambient temperatures create challenges that aren’t always obvious on paper. “Sometimes the weather temperature and the drink temperature are almost the same,” they explain. Keeping drinks hot, stable, and consistent requires careful adjustment. Customers still expect strong, well-balanced coffee, even in extreme heat, which means machines, recipes, and settings must be adapted specifically for the region.

Over the years, Bean Balance has also watched the Middle Eastern coffee scene mature. Traditional coffee remains deeply rooted, but modern specialty coffee has grown quickly. “Customers want better quality, new flavors, and well-made espressos,” they note. Cafés, baristas, and equipment have all evolved in response, raising expectations across the board.

To meet those expectations, Bean Balance doesn’t stop at installation. They cover everything from setup and calibration to barista training and round-the-clock support. That ongoing guidance is often what clients value most. “We don’t just install the machine,” they say. “We guide them, train their baristas, and help them make better coffee every day.”

A large part of that work happens before problems appear. Many of the most common issues cafés face are preventable: overheating, poor water quality, improper cleaning, or incorrect machine use. Left unchecked, these problems affect taste, consistency, and the lifespan of the machine itself. Bean Balance addresses them through regular maintenance, water filter checks, proper cleaning routines, and hands-on training. The goal is simple: fewer breakdowns, better coffee, and smoother daily operations.

Water, in particular, is a powerful factor. “Good water and correct calibration are very important for coffee quality,” they explain. Poor filtration can alter flavor and damage internal components, while incorrect calibration throws off recipes and consistency. Bean Balance assesses water quality carefully, installs filters suited to different boiler materials, and regularly calibrates grinders and machines to protect both the equipment and the cup.

Building trust wasn’t easy in the early days. Like many service businesses, Bean Balance faced challenges around costs, staffing, and credibility. They tackled these head-on by focusing on results. “We tried to fix issues on the first visit,” they say, and when possible, repaired components instead of replacing entire units. That approach saved customers money and reduced downtime, slowly building a reputation for honest, practical service.

Consistency remains a cornerstone of their work today. Their methodology remains the same whether servicing a single-group machine in a small café or a multi-machine setup in a hotel. Machines are checked thoroughly, calibrated correctly, cleaned properly, and tested with care. “We give the same attention, same care, and same quality service,” regardless of client size.

Behind the scenes, the team works hard to keep pace with changing technology. New machines, updated software, and evolving brewing techniques require constant learning. The team studies manuals, reviews new equipment, and tests solutions firsthand. This habit of continuous learning has also shaped how they see the future of the technician’s role.

There’s a common misconception that technicians simply fix broken machines. In reality, the job is far broader. “A good technician combines technical skills with coffee knowledge,” they explain. Success depends on understanding brewing pressure, grind size, water quality, and how small changes ripple through the system. Problem-solving and attention to detail matter just as much as tools.

Speaking of tools, there’s no single hero item. Temperature sensors, pressure gauges, scales, and standard hand tools all play their part, depending on the issue. What matters more is mindset. “We find the root cause and fix it properly, rather than just treating symptoms.”

That mindset was put to the test during one of their most memorable jobs. A machine installed overnight at Dubai Airport was incorrectly connected and burned out just hours before a café’s opening. With no room for delay, Bean Balance split into two teams. One went straight to the site while the other sourced spare parts immediately. Working together, they repaired the machine in time for the shop to open as scheduled. It was a complex repair, but also a clear example of what the company stands for: responsiveness, teamwork, and accountability.

Looking ahead, Bean Balance sees growth, expansion, and deeper specialization. Automation and smart machines will change the technician’s role, shifting more focus toward monitoring, programming, and data-driven maintenance. The company has already introduced a service history system that records detailed machine data, making troubleshooting faster and more accurate for current and future technicians.

At its core, though, the mission stays the same. Success is defined simply: machines that work properly, coffee that tastes great, and clients who feel supported. “Your trust motivates us to work harder and grow together with you,” they say.

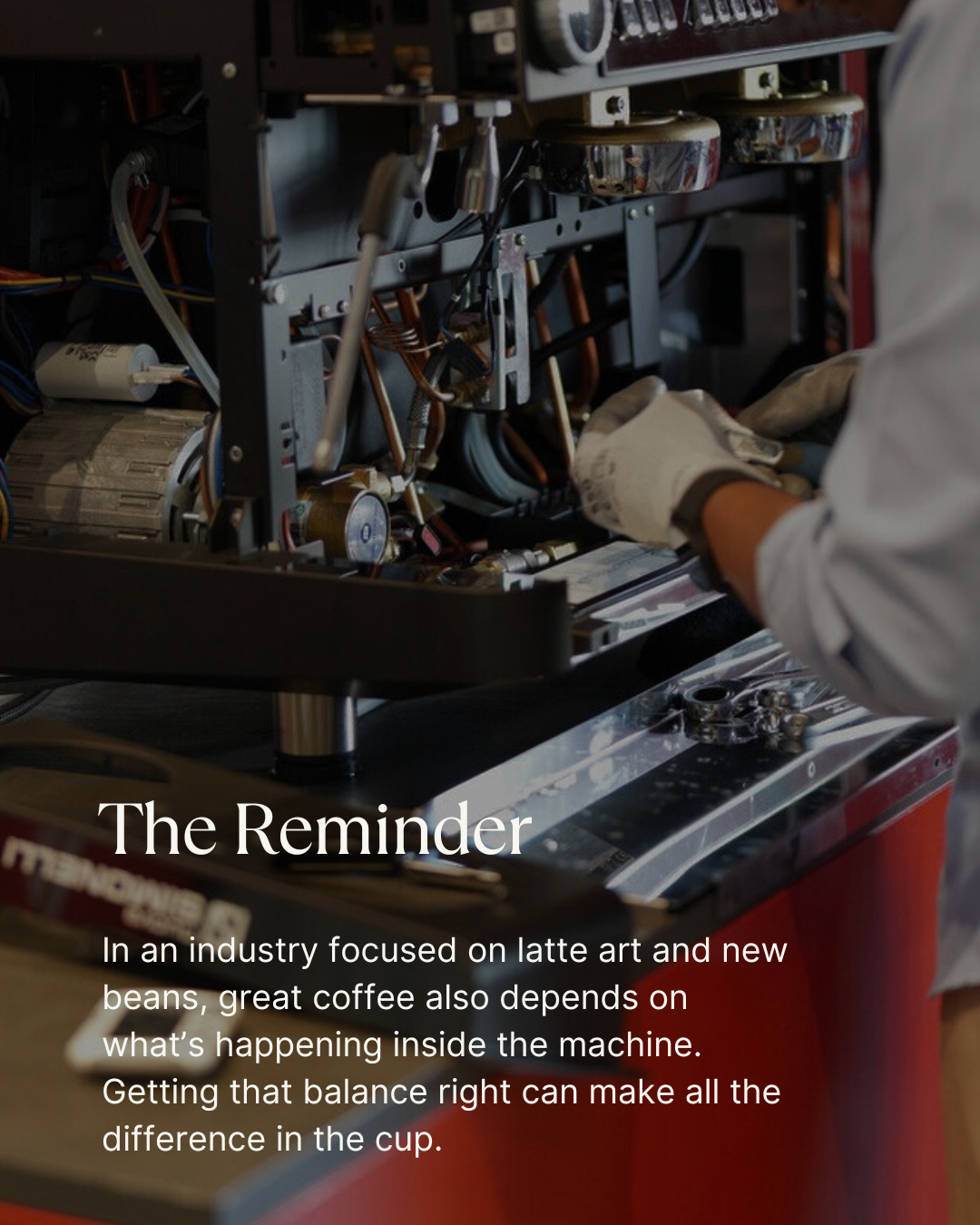

In an industry where the spotlight often falls on latte art and new beans, Bean Balance reminds us that great coffee also depends on what’s actually happening inside the machine. Getting that balance right can make all the difference in the cup.

Great coffee doesn’t stop at good beans or beautiful machines, it depends on how everything works together, day after day.

If you’re looking to improve consistency, protect your equipment, and deliver better coffee with confidence, this is the perfect time to meet the team behind Bean Balance.

They will at World of Coffee Dubai starting on the 18th of January. Contact them now and book an appointment.